$49.90

Operation and Test Manual

1Troubleshooting Manual

1Repair Manual

1Engine Technical Manual

1Operators Manual

1All-Inclusive Factory Service Technical manual for Hitachi Crawler Excavator or Crawler Excavators Models .

This manuals will assist you in diagnosing, troubleshooting, assembling, disassembling, repairing, repairing engine, and operating for your crawler excavator or crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 210-5G (PIN: 1FFDCDH1_ _C330001-)

Zaxis 210LC-5G (PIN: 1FFDCDH1_ _C330001-)

The manual comprises 5 documents, including the Operation and Test Manual, Troubleshooting Manual, Repair Manual, Engine Technical Manual, and Operators Manual

1. Operation and Test Manual (TM12628)

Format: PDF, 675 pages

Language: English

Publication Date: 19 Jan 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Diagnostics

Main Controller (MCZ) Diagnostic Trouble Codes

Engine Controller (ECF) Diagnostic Trouble Codes

Monitor Controller (DSZ) Diagnostic Trouble Codes

Air Conditioner Controller (ACF) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

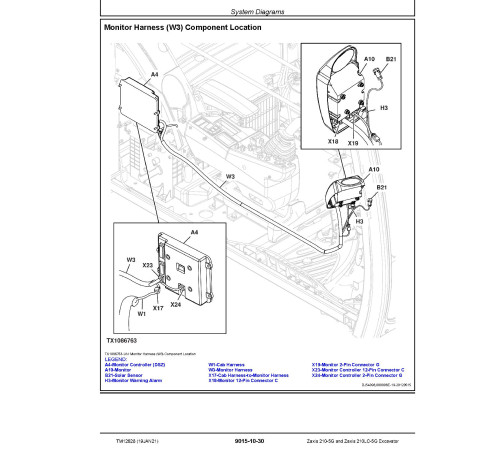

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Hydraulic System

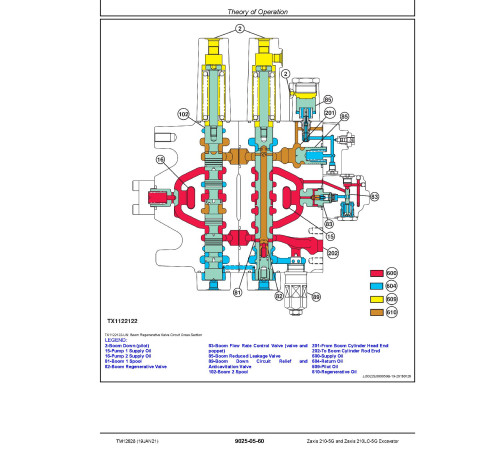

Theory of Operation

Diagnostic Information

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

Dealer Fabricated Tools

Dealer Fabricated Tools

Section 9000

Section 9001

Section 9005

Section 9010

Section 9015

Section 9020

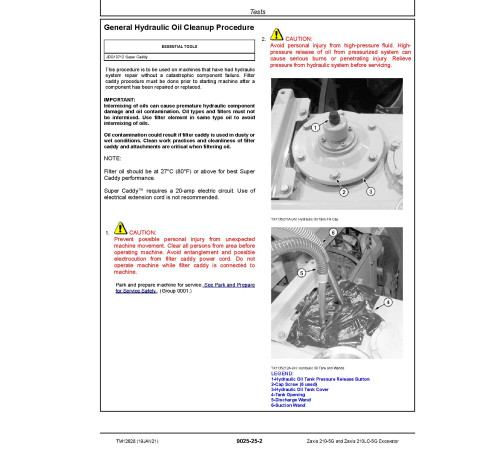

Section 9025

Section 9031

Section 9900

2. Troubleshooting Manual: Undercarriage Appraisal Manual (SP326VOL3)

Format: PDF, 531 pages

Language: English

Publication Date: 06 Dec 2019

Table of Contents:

General Information

Safety

Torque Values

Adjustments

Adjustments

Ground and Operating Conditions

Ground Conditions

Operating Conditions

Undercarriage Wear

Undercarriage Wear

Wear Measurement

Wear Measurement

Undercarriage Evaluation

Undercarriage Evaluation

Undercarriage Specifications

Introduction

Excavator

Forestry Excavator

Glossary

Glossary

3. Repair Manual (TM12632)

Format: PDF, 439 pages

Language: English

Publication Date: 18 Feb 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Torque Values

Tracks

Track System

Axles, Differentials, and Suspension Systems

Axle Shaft, Bearings, and Reduction Gears

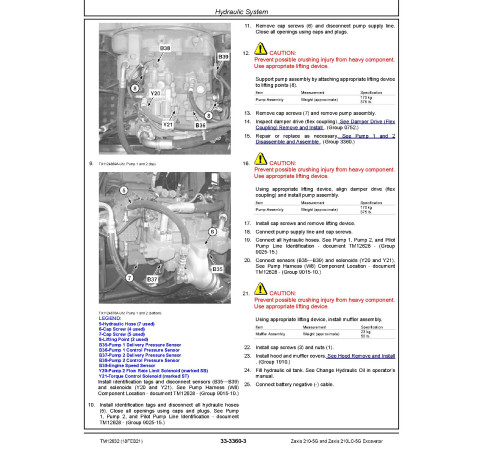

Hydraulic System

Engine

Removal and Installation

Engine Auxiliary System

Cooling Systems

Intake System

External Fuel Supply Systems

Damper Drive (Flex Coupling)

Elements

Frame or Supporting Structure

Frame Installation

Chassis Weights

Operator`s Station

Removal and Installation

Operator Enclosure

Seat and Seat Belt

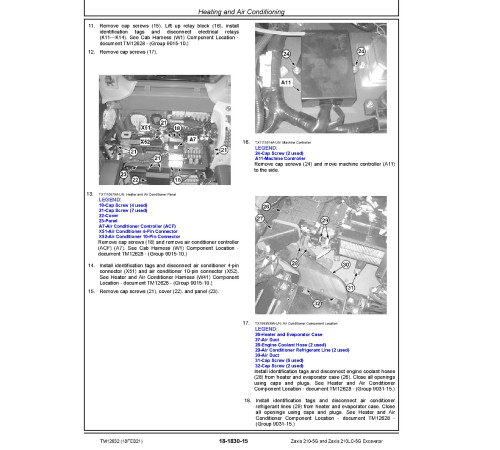

Heating and Air Conditioning

Sheet Metal

Hood and Engine Side Shields

Excavator

Buckets

Frames

Hydraulic System

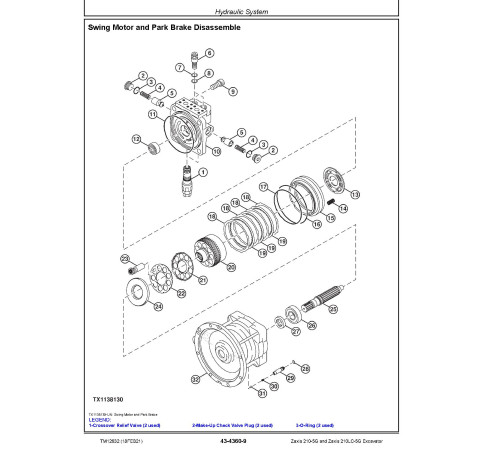

Swing or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

Dealer Fabricated Tools

4. Engine Technical Manual (EDCDEN00)

Format: PDF, 234 pages

Language: English

Table of Contents:

GENERAL INFORMATION

General repair instructions

Notes on the format of this manual

Main data and specifications

Performance curve

External view

Tightening torque specifications

Angular nut and bolt tightening method

Major parts fixing nuts and bolts

Identifications

MAINTENANCE

Lubricating system

Fuel system

Cooling system

Valve clearance adjustment

Injection timing

Compression pressure measurement

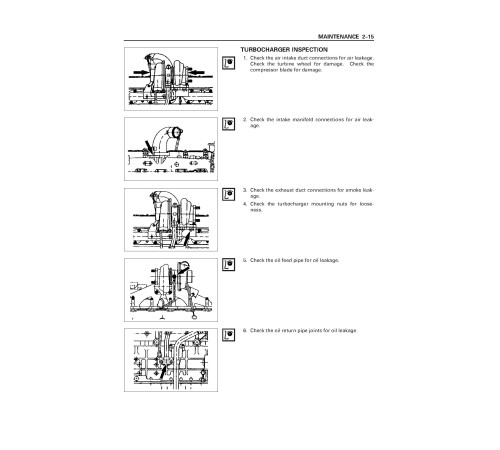

Turbocharger inspection

Engine repair kit

Recommended lubricants

Engine oil viscosity chart

ENGINE ASSEMBLY I

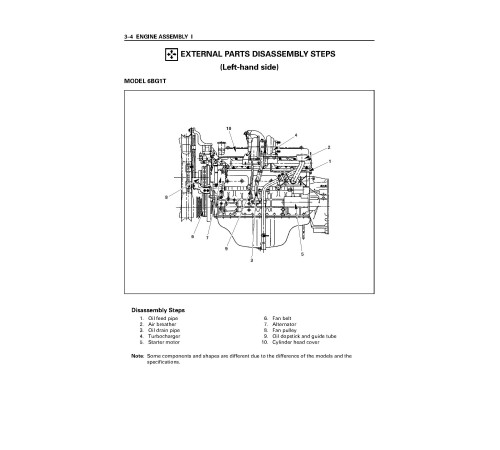

External parts disassembly steps

Major components

Rocker arm and rocker arm shaft disassembly steps

Cylinder head disassembly steps

Piston and connecting rod disassembly steps

ENGINE ASSEMBLY II

Cylinder head

Valve guide

Valve spring

Tappet

Push rod

Rocker arm shaft and rocker arm

Idler gear and idler gear shaft

Camshaft

Cylinder body and liner

Piston and piston ring

Piston pin

Connecting rod

Crankshaft

Flywheel

Timing gear case cover

ENGINE ASSEMBLY III

Piston and connecting rod reassembly steps

Cylinder head reassembly steps

Rocker arm and rocker arm shaft reassembly steps

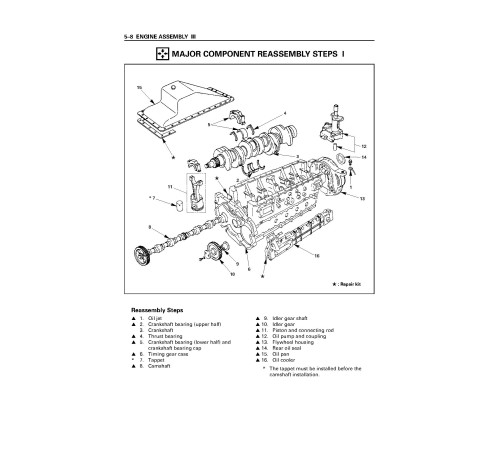

Major component reassembly steps I.

Major component reassembly steps II

External parts reassembly steps (Left-Hand Side)

External parts reassembly steps (Right-Hand Side)

Engine tuning operation

LUBRICATING SYSTEM

General description

Oil pump

Oil cooler

COOLING SYSTEM

General description

Thermostat

FUEL SYSTEM

General description

Injection nozzle

Injection pump calibration data

TURBOCHARGER

General description

Turbocharger identification

Troubleshooting

Inspection and repair

ENGINE ELECTRICALS

Starter identification

Starter main data and specifications

Starter sectional view

Performance

Disassembly

Inspection and repair

Reassembly

Adjustment

Performance test

Alternator identification

Main data and specifications

Alternator sectional view

Charging curcuit

Structure

Disassembly

Inspections

Reassembly

Bench test

Current output test

Fault finding

Specifications

TROUBLESHOOTING

Hard starting

Unstable low idling

Insufficient power

Excessive fuel consumption

Excessive oil consumption

Overheating

White exhaust smoke

Dark exhaust smoke

Oil pressure does not rise

Abnormal engine noise

SPECIAL TOOL LIST

Special tool list

REPAIR STANDARDS

CONVERSION TABLE

LENGTH

AREA

VOLUME

MASS

PRESSURE

TORQUE

TEMPERATURE

5. Operators Manual (ENMDCDLA34)

Format: PDF, 436 pages

Language: English

Table of Contents:

INTRODUCTION

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

GETTING ON/OFF THE MACHINE

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENTS AND DEVICES

INDEX

This manuals will assist you in diagnosing, troubleshooting, assembling, disassembling, repairing, repairing engine, and operating for your crawler excavator or crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 210-5G (PIN: 1FFDCDH1_ _C330001-)

Zaxis 210LC-5G (PIN: 1FFDCDH1_ _C330001-)

The manual comprises 5 documents, including the Operation and Test Manual, Troubleshooting Manual, Repair Manual, Engine Technical Manual, and Operators Manual

1. Operation and Test Manual (TM12628)

Format: PDF, 675 pages

Language: English

Publication Date: 19 Jan 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Diagnostics

Main Controller (MCZ) Diagnostic Trouble Codes

Engine Controller (ECF) Diagnostic Trouble Codes

Monitor Controller (DSZ) Diagnostic Trouble Codes

Air Conditioner Controller (ACF) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Hydraulic System

Theory of Operation

Diagnostic Information

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

Dealer Fabricated Tools

Dealer Fabricated Tools

Section 9000

Section 9001

Section 9005

Section 9010

Section 9015

Section 9020

Section 9025

Section 9031

Section 9900

2. Troubleshooting Manual: Undercarriage Appraisal Manual (SP326VOL3)

Format: PDF, 531 pages

Language: English

Publication Date: 06 Dec 2019

Table of Contents:

General Information

Safety

Torque Values

Adjustments

Adjustments

Ground and Operating Conditions

Ground Conditions

Operating Conditions

Undercarriage Wear

Undercarriage Wear

Wear Measurement

Wear Measurement

Undercarriage Evaluation

Undercarriage Evaluation

Undercarriage Specifications

Introduction

Excavator

Forestry Excavator

Glossary

Glossary

3. Repair Manual (TM12632)

Format: PDF, 439 pages

Language: English

Publication Date: 18 Feb 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Torque Values

Tracks

Track System

Axles, Differentials, and Suspension Systems

Axle Shaft, Bearings, and Reduction Gears

Hydraulic System

Engine

Removal and Installation

Engine Auxiliary System

Cooling Systems

Intake System

External Fuel Supply Systems

Damper Drive (Flex Coupling)

Elements

Frame or Supporting Structure

Frame Installation

Chassis Weights

Operator`s Station

Removal and Installation

Operator Enclosure

Seat and Seat Belt

Heating and Air Conditioning

Sheet Metal

Hood and Engine Side Shields

Excavator

Buckets

Frames

Hydraulic System

Swing or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

Dealer Fabricated Tools

4. Engine Technical Manual (EDCDEN00)

Format: PDF, 234 pages

Language: English

Table of Contents:

GENERAL INFORMATION

General repair instructions

Notes on the format of this manual

Main data and specifications

Performance curve

External view

Tightening torque specifications

Angular nut and bolt tightening method

Major parts fixing nuts and bolts

Identifications

MAINTENANCE

Lubricating system

Fuel system

Cooling system

Valve clearance adjustment

Injection timing

Compression pressure measurement

Turbocharger inspection

Engine repair kit

Recommended lubricants

Engine oil viscosity chart

ENGINE ASSEMBLY I

External parts disassembly steps

Major components

Rocker arm and rocker arm shaft disassembly steps

Cylinder head disassembly steps

Piston and connecting rod disassembly steps

ENGINE ASSEMBLY II

Cylinder head

Valve guide

Valve spring

Tappet

Push rod

Rocker arm shaft and rocker arm

Idler gear and idler gear shaft

Camshaft

Cylinder body and liner

Piston and piston ring

Piston pin

Connecting rod

Crankshaft

Flywheel

Timing gear case cover

ENGINE ASSEMBLY III

Piston and connecting rod reassembly steps

Cylinder head reassembly steps

Rocker arm and rocker arm shaft reassembly steps

Major component reassembly steps I.

Major component reassembly steps II

External parts reassembly steps (Left-Hand Side)

External parts reassembly steps (Right-Hand Side)

Engine tuning operation

LUBRICATING SYSTEM

General description

Oil pump

Oil cooler

COOLING SYSTEM

General description

Thermostat

FUEL SYSTEM

General description

Injection nozzle

Injection pump calibration data

TURBOCHARGER

General description

Turbocharger identification

Troubleshooting

Inspection and repair

ENGINE ELECTRICALS

Starter identification

Starter main data and specifications

Starter sectional view

Performance

Disassembly

Inspection and repair

Reassembly

Adjustment

Performance test

Alternator identification

Main data and specifications

Alternator sectional view

Charging curcuit

Structure

Disassembly

Inspections

Reassembly

Bench test

Current output test

Fault finding

Specifications

TROUBLESHOOTING

Hard starting

Unstable low idling

Insufficient power

Excessive fuel consumption

Excessive oil consumption

Overheating

White exhaust smoke

Dark exhaust smoke

Oil pressure does not rise

Abnormal engine noise

SPECIAL TOOL LIST

Special tool list

REPAIR STANDARDS

CONVERSION TABLE

LENGTH

AREA

VOLUME

MASS

PRESSURE

TORQUE

TEMPERATURE

5. Operators Manual (ENMDCDLA34)

Format: PDF, 436 pages

Language: English

Table of Contents:

INTRODUCTION

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

GETTING ON/OFF THE MACHINE

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENTS AND DEVICES

INDEX

Included

Operation and Test Manual

1Troubleshooting Manual

1Repair Manual

1Engine Technical Manual

1Operators Manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Similar products