$49.90

Operation and Test Manual

1Troubleshooting Manual

1Repair Manual

1Engine Technical Manual

2Operators Manual

2All-Inclusive Factory Service Technical manual for Hitachi Compact Excavator or Compact Excavators Models .

This manuals will assist you in diagnosing, troubleshooting, assembling, disassembling, repairing, repairing engine, and operating for your compact excavator or compact excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 50U-5N (PIN: HCMAED60_ _0280003-)

The manual comprises 7 documents, including the Operation and Test Manual, Troubleshooting Manual, Repair Manual, two Engine Technical Manuals, and two Operators Manuals

1. Operation and Test Manual (TM12915)

Format: PDF, 389 pages

Language: English

Publication Date: 13 May 2021

Table of Contents:

Diagnostics

Engine Control Unit (ECU) Diagnostic Trouble Codes

Monitor Controller (DSZ) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

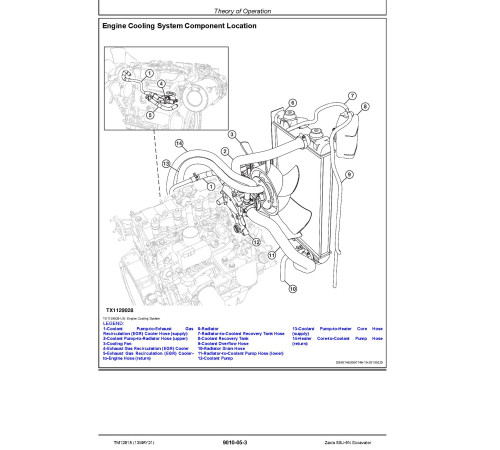

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

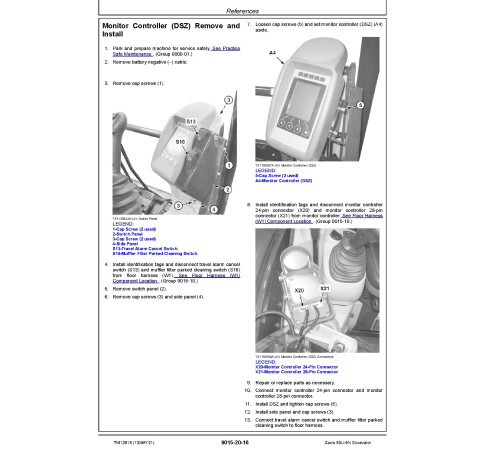

References

Power Train

Theory of Operation

Diagnostic Information

Hydraulic System

Theory of Operation

Diagnostic Information

Tests

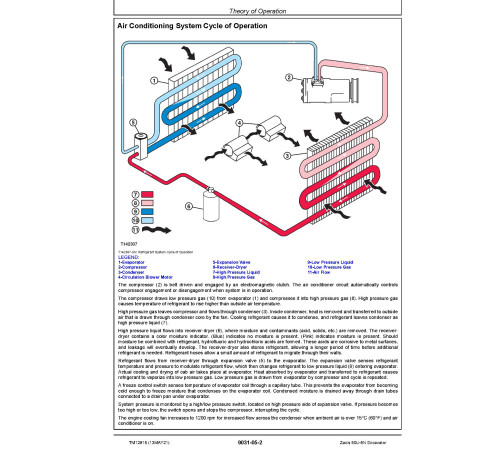

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

APPENDIX

2. Troubleshooting Manual: Undercarriage Appraisal Manual (SP326VOL3)

Format: PDF, 531 pages

Language: English

Publication Date: 06 Dec 2019

Table of Contents:

General Information

Safety

Torque Values

Adjustments

Adjustments

Ground and Operating Conditions

Ground Conditions

Operating Conditions

Undercarriage Wear

Undercarriage Wear

Wear Measurement

Wear Measurement

Undercarriage Evaluation

Undercarriage Evaluation

Undercarriage Specifications

Introduction

Excavator

Forestry Excavator

Glossary

Glossary

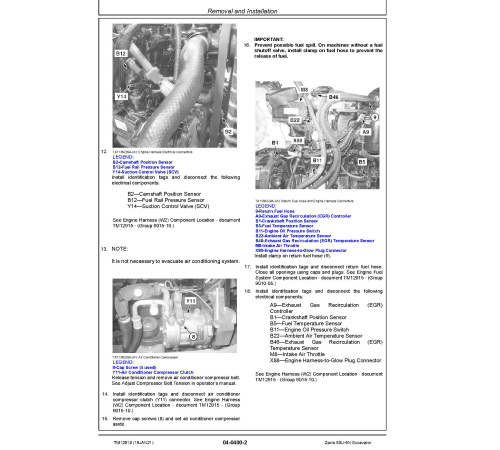

3. Repair Manual (TM12918)

Format: PDF, 381 pages

Language: English

Publication Date: 19 Jan 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Torque Values

Tracks

Track System

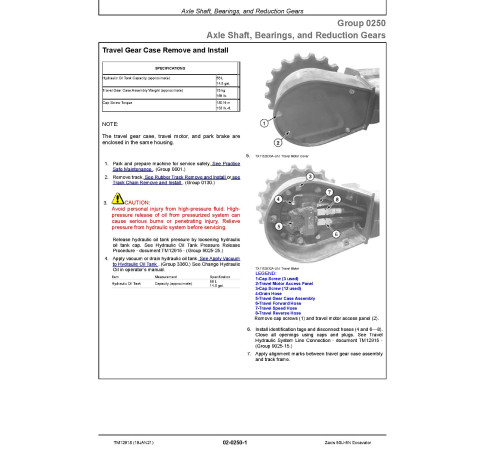

Axles and Suspension Systems (Travel)

Axle Shaft, Bearings, and Reduction Gears

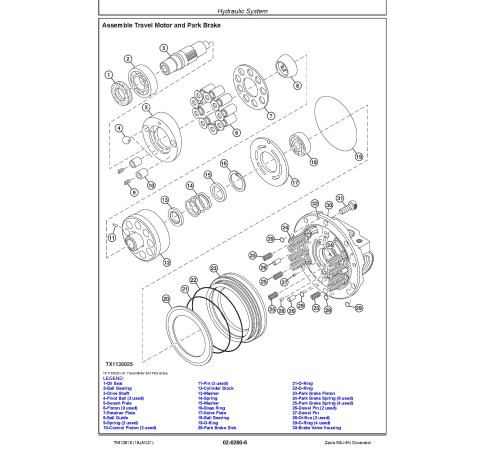

Hydraulic System

Engine

Removal and Installation

Engine Auxiliary System

Cooling Systems

External Exhaust Systems

External Fuel Supply Systems

Damper Drive (Flex Coupling)

Elements

Frame or Supporting Structure

Frame Installation

Chassis Weights

Operator`s Station

Removal and Installation

Operator Enclosure

Seat and Seat Belt

Heating and Air Conditioning System

Blade (Backfill)

Blades

Hydraulic System

Excavator

Buckets

Frames

Hydraulic System

Swing or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

Dealer Fabricated Tools

hitachi-cover.pdf

4. Engine Technical Manual (0DTN4-G00200)

Format: PDF, 404 pages

Language: English

Table of Contents:

COVER

1. DTC (Diagnostic Trouble Codes) General Description

DTC code list

Description

Sensor related

Contact output related

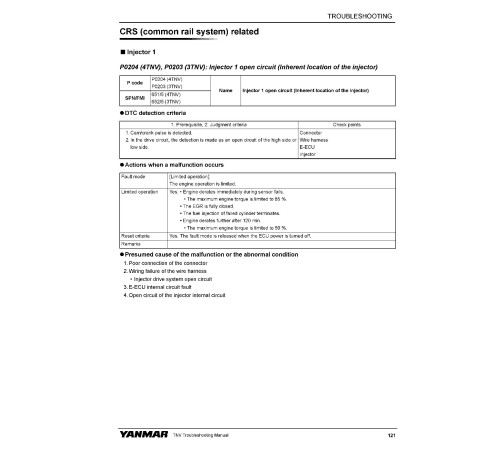

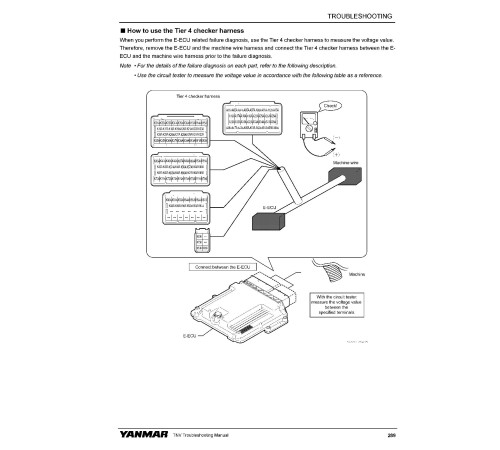

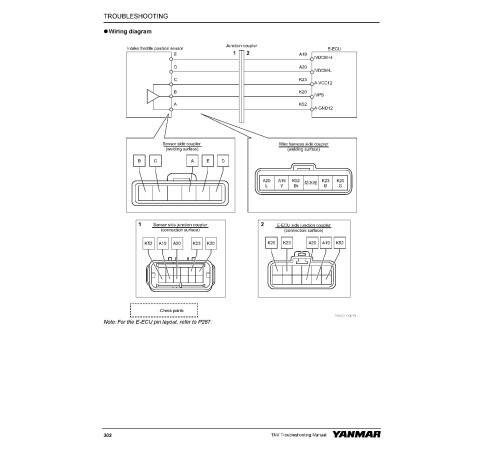

CRS (common rail system) related

Actuator

Communication related

ECU related

Contact input related

Post treatment control

Others

2. Method and Procedure of Failure Diagnosis

Description

Sensor related

Contact output related

Contact input related

CRS (common rail system) related

Actuator

Communication related

ECU related

Others

5. Engine Technical Manual (0BTN4G00201)

Format: PDF, 304 pages

Language: English

Table of Contents:

Cover

Table of Contents

Introduction

YANMAR Warranties

YANMAR Limited Warranty

Emission System Warranty

YANMAR Co., Ltd. Limited Emission Control System Warranty - USA Only

Safety

Safety Statements

Safety Precautions

General Service Information

Component Identification

Location of Labels

Emission Control Regulations

Emission Control Labels

Engine Family

Function of Major Engine Components

Function of Cooling System Components

Main Electronic Control Components and Features

Installation Position of Sensors

Diesel Fuel

Engine Oil

Engine Coolant

Specifications

Principal Engine Specifications

Engine Service Standards

Tightening Torques for Standard Bolts and Nuts

Abbreviations and Symbols

Unit Conversions

Periodic Maintenance

Before You Begin Servicing

Introduction

Periodic Maintenance Schedule

Periodic Maintenance Procedures

Engine

Before You Begin Servicing

Introduction

Cylinder Head Specifications

Camshaft and Timing Gear Train Specifications

Crankshaft and Piston Specifications

Cylinder Block Specifications

Special Torque Chart

Special Service Tools

Measuring Instruments

Cylinder Head

Measuring and Adjusting Valve Clearance

Crankshaft and Camshaft Components

EGR System

Intake Throttle

Fuel System

Before You Begin Servicing

System Structure

Fuel System Specifications

Fuel System Diagram

Fuel System Components

Cooling System

Before You Begin Servicing

Introduction

Cooling System Diagram

Engine Coolant Pump Components

Engine Coolant System Check

Engine Coolant Pump

Lubrication System

Before You Begin Servicing

Introduction

Oil Pump Service Information

Lubrication System Diagram

Checking Engine Oil Pressure

Oil Pump Components

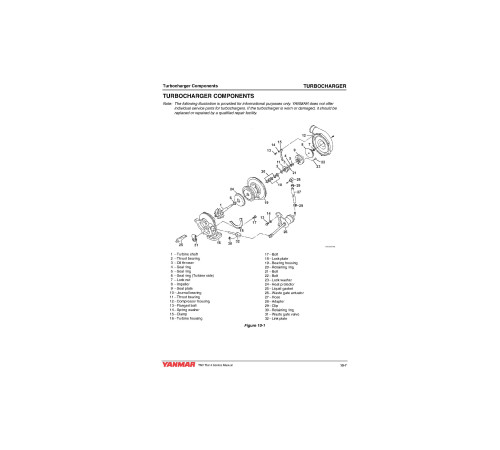

Turbocharger

Before You Begin Servicing

Introduction

Specifications

Troubleshooting

Turbocharger Components

Turbocharger Component Functions

Washing Procedure

Periodic Inspection

Starter Motor

Before You Begin Servicing

Introduction

Starter Motor Information

Starter Motor Specifications

Starter Motor Troubleshooting

Starter Motor Components

Starter Motor

Alternator

Before You Begin Servicing

Introduction

Dynamo and Alternator Information

Alternator Specifications

Dynamo Specifications

Alternator Troubleshooting

Alternator Components

Alternator Wiring Diagram

Alternator Standard Output

Alternator

Dynamo Component Location

Dynamo Wiring Diagram

Operation of Dynamo

Dynamo Standard Output

Testing of Dynamo

Dynamo

Electronic Control System

Before You Begin Servicing

System Structure

Troubleshooting of Electronic Control System

Replacement of Components

Electronic Control Harness Connections

Electric Wiring

Electric Wiring Precautions

Electrical Wire Resistance

Battery Cable Resistance

Electrical Wire Sizes - Voltage Drop

Conversion of AWG to European Standards

Failure Diagnosis

Special Service Tools

Tier 4 (BOSCH) Compression Inspection Procedures

Measured Value and Troubleshooting

Quick Reference Table for Troubleshooting

6. Operators Manual (ENMADGNA22)

Format: PDF, 343 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

Machine

Product Identification Number

Engine

Muffler Filter

DOC (Diesel Oxidation Catalyst)

Travel Motor

Hydraulic Pump

SAFETY

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Prepare For Emergencies

Wear Protective Clothing

Protect Against Noise

Inspect Machine

General Precautions for Cab

Use Handrails and Steps

Adjust the Operator’s Seat

Ensure Safety Before Rising From or Leaving Operator’s Seat

Fasten Your Seat Belt

Move and Operate Machine Safely

Operate Only From Operator’s Seat

Jump Starting

Keep Riders Off Machine

Precautions for Operations

Investigate Job Site Beforehand

Equipment of OPG

Restriction of Attachment Installation

Provide Signals for Jobs Involving Multiple Machines

Confirm Direction of Machine to be Driven

Drive Machine Safely

Avoid Injury From Rollaway Accidents

Avoid Injury From Back-over and Swing Accidents

Keep Person Clear From Working Area

Never Position Bucket Over Anyone

Avoid Undercutting

Avoid Tipping

Never Undercut a High Bank

Dig With Caution

Operate With Caution

Avoid Power Lines

Precautions for Lightning

Object Handling

Protect Against Flying Debris

Park Machine Safely

Handle Fluids Safely --- Avoid Fires

Safety Transporting

Practice Safe Maintenance

Warn Others of Service Work

Support Machine Properly

Stay Clear of Moving Parts

Prevent Parts From Flying

Avoid Injury from Attachment Falling Accident

Prevent Burns

Replace Rubber Hoses Periodically

Avoid High-Pressure Fluids

Prevent Fires

Evacuating in Case of Fire

Beware of Exhaust Fumes

Precautions for Welding and Grinding

Avoid Heating Near Pressurized Fluid Lines

Avoid Applying Heat to Lines Containing Flammable Fluids

Precautions for Handling Accumulator and Gas Damper

Remove Paint Before Welding or Heating

Beware of Asbestos and Silicon Dust and Other Contamination

Prevent Battery Explosions

Precautions for Handling Refrigerant

Handle Chemical Products Safely

Dispose of Waste Properly

Never Ride Attachment

Notes for Muffler Filter (ZX50U-5N, 60USB-5N)

Precautions for Communication Terminal

Notes on Protection of Operator’s Station When the Machine Rolls Over

SAFETY SIGNS

COMPONENTS NAME

GETTING ON/OFF THE MACHINE

OPERATOR'S STATION

Muffler Filter (ZX50U-5N, 60USB-5N)

Layout

Monitor

Basic Screen

Indicators

How to Use Screens

Alarm Occurrence Screen

Contents of Alarms

DTC Code List

Muffler Filter (ZX50U-5N, 60USB-5N)

Muffler Filter (ZX50U-5N, 60USB-5N)

Main Menu (MENU)

Auto Shut-Down

Muffler Filter Regeneration Inhibited (ZX50U-5N, 60USB-5N)

Clock

Trip

Brightness Adjustment

Heater Operation (ZX30U-5N, 35U-5N, 50U-5N)

Tips for Optimal Heater Usage

Air Conditioner Operation (Optional)

Tips for Optimal Air Conditioner Usage

Radio (Cab equipped machine) (Optional)

AM/FM Radio Operation (Cab equipped machine)

Door Lock Release Lever (Cab equipped machine)

Opening Upper Front Window (cab equipped machine)

Adjusting the Seat

Tool Box

Seat Back Box

Emergency Exit (cab equipped machine)

Seat Belt

BREAK-IN

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting Engine

Starting the Engine

Check Instruments After Starting Engine

Using Booster Battery

Stopping the Engine

DRIVING THE MACHINE

Travel Levers and Pedals (Optional)

Travel Mode Switch

Traveling

Traveling on Soft Ground

Raise One Track Using Boom and Arm

Towing Machine

Operating in Water or Mud

Precautions for Traveling on Slopes

Parking the Machine on Slopes

OPERATING THE MACHINE

Control Lever (ISO Pattern)

Boom-Swing Pedal

Blade Lever

Precautions for Blade Operation

Pilot Control Shut-Off Lever

Warming Up Operation

Engine Speed Control

Auto-Idle

Auto Shut-Down

Muffler Filter Manual Regeneration

Power Mode

Operating Backhoe

Grading Operation

Avoid Abusive Operation

Avoid Excavation Using Upperstructure and/or Boom Swing Power

Avoid Driving Bucket Teeth into Ground

Avoid Striking With Bucket

Boom Cylinder may Hit Blade

Avoid Hitting Blade With Bucket

Avoid Colliding Blade Against Rocks

Avoid Colliding Boom Cylinder With Track

Precautions for Installing Wide Bucket or Special Type Bucket

Use Correct Track Shoe

Using Rubber Crawler

Avoid other than Specified Machine Operations

Shackle Bracket Usage

Emergency Boom Lowering Procedure

Precautions for After Operations

TRANSPORTING

Transporting by Road

Loading/Unloading on a Truck

Fastening Machine for Transporting

Unloading

Lifting Machine

MAINTENANCE

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Layout

Maintenance Guide Table

Preparations for Inspection and Maintenance

Access Covers

Maintenance Guide

Periodic Replacement of Parts

Kind of Oils

Greasing

Engine

Transmission

Hydraulic System

Fuel System

Air Cleaner

Cooling System

Electrical System

Miscellaneous

Muffler Filter (ZX50U-5N, 60USB-5N)

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

Std. SpecificationZX30U-5N

Working RangesZX30U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX30U-5N

Std. SpecificationZX35U-5N

Working RangesZX35U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX35U-5N

Std. SpecificationZX50U-5N

Working RangesZX50U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX50U-5N

Std. SpecificationZX60USB-5N

Working RangesZX60USB-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX60USB-5N

OPTIONAL ATTACHMENT

Hydraulic Breaker, Hydraulic Crusher and QuickCoupler

Attachment

Piping for Breaker and Crusher (Optional)

AUX Function Lever for Extra Piping (Optional)

Precautions for Breaker Operation

Precautions for Crusher Operation

Control Lever (SAE-backhoe Pattern)

Fuel Feed Device (Optional) (ZX50U-5N, 60USB-5N)

Additional Counterweight

Cab Tilting Mechanism

INDEX

7. Operators Manual: Angle Blade (ENMADGNAOP13)

Format: PDF, 22 pages

Language: English

This manuals will assist you in diagnosing, troubleshooting, assembling, disassembling, repairing, repairing engine, and operating for your compact excavator or compact excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 50U-5N (PIN: HCMAED60_ _0280003-)

The manual comprises 7 documents, including the Operation and Test Manual, Troubleshooting Manual, Repair Manual, two Engine Technical Manuals, and two Operators Manuals

1. Operation and Test Manual (TM12915)

Format: PDF, 389 pages

Language: English

Publication Date: 13 May 2021

Table of Contents:

Diagnostics

Engine Control Unit (ECU) Diagnostic Trouble Codes

Monitor Controller (DSZ) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Hydraulic System

Theory of Operation

Diagnostic Information

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

APPENDIX

2. Troubleshooting Manual: Undercarriage Appraisal Manual (SP326VOL3)

Format: PDF, 531 pages

Language: English

Publication Date: 06 Dec 2019

Table of Contents:

General Information

Safety

Torque Values

Adjustments

Adjustments

Ground and Operating Conditions

Ground Conditions

Operating Conditions

Undercarriage Wear

Undercarriage Wear

Wear Measurement

Wear Measurement

Undercarriage Evaluation

Undercarriage Evaluation

Undercarriage Specifications

Introduction

Excavator

Forestry Excavator

Glossary

Glossary

3. Repair Manual (TM12918)

Format: PDF, 381 pages

Language: English

Publication Date: 19 Jan 2021

Table of Contents:

Introduction

Foreword

Technical Information Feedback Form

General Information

Safety

Torque Values

Tracks

Track System

Axles and Suspension Systems (Travel)

Axle Shaft, Bearings, and Reduction Gears

Hydraulic System

Engine

Removal and Installation

Engine Auxiliary System

Cooling Systems

External Exhaust Systems

External Fuel Supply Systems

Damper Drive (Flex Coupling)

Elements

Frame or Supporting Structure

Frame Installation

Chassis Weights

Operator`s Station

Removal and Installation

Operator Enclosure

Seat and Seat Belt

Heating and Air Conditioning System

Blade (Backfill)

Blades

Hydraulic System

Excavator

Buckets

Frames

Hydraulic System

Swing or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

Dealer Fabricated Tools

hitachi-cover.pdf

4. Engine Technical Manual (0DTN4-G00200)

Format: PDF, 404 pages

Language: English

Table of Contents:

COVER

1. DTC (Diagnostic Trouble Codes) General Description

DTC code list

Description

Sensor related

Contact output related

CRS (common rail system) related

Actuator

Communication related

ECU related

Contact input related

Post treatment control

Others

2. Method and Procedure of Failure Diagnosis

Description

Sensor related

Contact output related

Contact input related

CRS (common rail system) related

Actuator

Communication related

ECU related

Others

5. Engine Technical Manual (0BTN4G00201)

Format: PDF, 304 pages

Language: English

Table of Contents:

Cover

Table of Contents

Introduction

YANMAR Warranties

YANMAR Limited Warranty

Emission System Warranty

YANMAR Co., Ltd. Limited Emission Control System Warranty - USA Only

Safety

Safety Statements

Safety Precautions

General Service Information

Component Identification

Location of Labels

Emission Control Regulations

Emission Control Labels

Engine Family

Function of Major Engine Components

Function of Cooling System Components

Main Electronic Control Components and Features

Installation Position of Sensors

Diesel Fuel

Engine Oil

Engine Coolant

Specifications

Principal Engine Specifications

Engine Service Standards

Tightening Torques for Standard Bolts and Nuts

Abbreviations and Symbols

Unit Conversions

Periodic Maintenance

Before You Begin Servicing

Introduction

Periodic Maintenance Schedule

Periodic Maintenance Procedures

Engine

Before You Begin Servicing

Introduction

Cylinder Head Specifications

Camshaft and Timing Gear Train Specifications

Crankshaft and Piston Specifications

Cylinder Block Specifications

Special Torque Chart

Special Service Tools

Measuring Instruments

Cylinder Head

Measuring and Adjusting Valve Clearance

Crankshaft and Camshaft Components

EGR System

Intake Throttle

Fuel System

Before You Begin Servicing

System Structure

Fuel System Specifications

Fuel System Diagram

Fuel System Components

Cooling System

Before You Begin Servicing

Introduction

Cooling System Diagram

Engine Coolant Pump Components

Engine Coolant System Check

Engine Coolant Pump

Lubrication System

Before You Begin Servicing

Introduction

Oil Pump Service Information

Lubrication System Diagram

Checking Engine Oil Pressure

Oil Pump Components

Turbocharger

Before You Begin Servicing

Introduction

Specifications

Troubleshooting

Turbocharger Components

Turbocharger Component Functions

Washing Procedure

Periodic Inspection

Starter Motor

Before You Begin Servicing

Introduction

Starter Motor Information

Starter Motor Specifications

Starter Motor Troubleshooting

Starter Motor Components

Starter Motor

Alternator

Before You Begin Servicing

Introduction

Dynamo and Alternator Information

Alternator Specifications

Dynamo Specifications

Alternator Troubleshooting

Alternator Components

Alternator Wiring Diagram

Alternator Standard Output

Alternator

Dynamo Component Location

Dynamo Wiring Diagram

Operation of Dynamo

Dynamo Standard Output

Testing of Dynamo

Dynamo

Electronic Control System

Before You Begin Servicing

System Structure

Troubleshooting of Electronic Control System

Replacement of Components

Electronic Control Harness Connections

Electric Wiring

Electric Wiring Precautions

Electrical Wire Resistance

Battery Cable Resistance

Electrical Wire Sizes - Voltage Drop

Conversion of AWG to European Standards

Failure Diagnosis

Special Service Tools

Tier 4 (BOSCH) Compression Inspection Procedures

Measured Value and Troubleshooting

Quick Reference Table for Troubleshooting

6. Operators Manual (ENMADGNA22)

Format: PDF, 343 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

Machine

Product Identification Number

Engine

Muffler Filter

DOC (Diesel Oxidation Catalyst)

Travel Motor

Hydraulic Pump

SAFETY

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Prepare For Emergencies

Wear Protective Clothing

Protect Against Noise

Inspect Machine

General Precautions for Cab

Use Handrails and Steps

Adjust the Operator’s Seat

Ensure Safety Before Rising From or Leaving Operator’s Seat

Fasten Your Seat Belt

Move and Operate Machine Safely

Operate Only From Operator’s Seat

Jump Starting

Keep Riders Off Machine

Precautions for Operations

Investigate Job Site Beforehand

Equipment of OPG

Restriction of Attachment Installation

Provide Signals for Jobs Involving Multiple Machines

Confirm Direction of Machine to be Driven

Drive Machine Safely

Avoid Injury From Rollaway Accidents

Avoid Injury From Back-over and Swing Accidents

Keep Person Clear From Working Area

Never Position Bucket Over Anyone

Avoid Undercutting

Avoid Tipping

Never Undercut a High Bank

Dig With Caution

Operate With Caution

Avoid Power Lines

Precautions for Lightning

Object Handling

Protect Against Flying Debris

Park Machine Safely

Handle Fluids Safely --- Avoid Fires

Safety Transporting

Practice Safe Maintenance

Warn Others of Service Work

Support Machine Properly

Stay Clear of Moving Parts

Prevent Parts From Flying

Avoid Injury from Attachment Falling Accident

Prevent Burns

Replace Rubber Hoses Periodically

Avoid High-Pressure Fluids

Prevent Fires

Evacuating in Case of Fire

Beware of Exhaust Fumes

Precautions for Welding and Grinding

Avoid Heating Near Pressurized Fluid Lines

Avoid Applying Heat to Lines Containing Flammable Fluids

Precautions for Handling Accumulator and Gas Damper

Remove Paint Before Welding or Heating

Beware of Asbestos and Silicon Dust and Other Contamination

Prevent Battery Explosions

Precautions for Handling Refrigerant

Handle Chemical Products Safely

Dispose of Waste Properly

Never Ride Attachment

Notes for Muffler Filter (ZX50U-5N, 60USB-5N)

Precautions for Communication Terminal

Notes on Protection of Operator’s Station When the Machine Rolls Over

SAFETY SIGNS

COMPONENTS NAME

GETTING ON/OFF THE MACHINE

OPERATOR'S STATION

Muffler Filter (ZX50U-5N, 60USB-5N)

Layout

Monitor

Basic Screen

Indicators

How to Use Screens

Alarm Occurrence Screen

Contents of Alarms

DTC Code List

Muffler Filter (ZX50U-5N, 60USB-5N)

Muffler Filter (ZX50U-5N, 60USB-5N)

Main Menu (MENU)

Auto Shut-Down

Muffler Filter Regeneration Inhibited (ZX50U-5N, 60USB-5N)

Clock

Trip

Brightness Adjustment

Heater Operation (ZX30U-5N, 35U-5N, 50U-5N)

Tips for Optimal Heater Usage

Air Conditioner Operation (Optional)

Tips for Optimal Air Conditioner Usage

Radio (Cab equipped machine) (Optional)

AM/FM Radio Operation (Cab equipped machine)

Door Lock Release Lever (Cab equipped machine)

Opening Upper Front Window (cab equipped machine)

Adjusting the Seat

Tool Box

Seat Back Box

Emergency Exit (cab equipped machine)

Seat Belt

BREAK-IN

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting Engine

Starting the Engine

Check Instruments After Starting Engine

Using Booster Battery

Stopping the Engine

DRIVING THE MACHINE

Travel Levers and Pedals (Optional)

Travel Mode Switch

Traveling

Traveling on Soft Ground

Raise One Track Using Boom and Arm

Towing Machine

Operating in Water or Mud

Precautions for Traveling on Slopes

Parking the Machine on Slopes

OPERATING THE MACHINE

Control Lever (ISO Pattern)

Boom-Swing Pedal

Blade Lever

Precautions for Blade Operation

Pilot Control Shut-Off Lever

Warming Up Operation

Engine Speed Control

Auto-Idle

Auto Shut-Down

Muffler Filter Manual Regeneration

Power Mode

Operating Backhoe

Grading Operation

Avoid Abusive Operation

Avoid Excavation Using Upperstructure and/or Boom Swing Power

Avoid Driving Bucket Teeth into Ground

Avoid Striking With Bucket

Boom Cylinder may Hit Blade

Avoid Hitting Blade With Bucket

Avoid Colliding Blade Against Rocks

Avoid Colliding Boom Cylinder With Track

Precautions for Installing Wide Bucket or Special Type Bucket

Use Correct Track Shoe

Using Rubber Crawler

Avoid other than Specified Machine Operations

Shackle Bracket Usage

Emergency Boom Lowering Procedure

Precautions for After Operations

TRANSPORTING

Transporting by Road

Loading/Unloading on a Truck

Fastening Machine for Transporting

Unloading

Lifting Machine

MAINTENANCE

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Layout

Maintenance Guide Table

Preparations for Inspection and Maintenance

Access Covers

Maintenance Guide

Periodic Replacement of Parts

Kind of Oils

Greasing

Engine

Transmission

Hydraulic System

Fuel System

Air Cleaner

Cooling System

Electrical System

Miscellaneous

Muffler Filter (ZX50U-5N, 60USB-5N)

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

Std. SpecificationZX30U-5N

Working RangesZX30U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX30U-5N

Std. SpecificationZX35U-5N

Working RangesZX35U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX35U-5N

Std. SpecificationZX50U-5N

Working RangesZX50U-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX50U-5N

Std. SpecificationZX60USB-5N

Working RangesZX60USB-5N

Shoe Types and Applications

Bucket Types and ApplicationsZX60USB-5N

OPTIONAL ATTACHMENT

Hydraulic Breaker, Hydraulic Crusher and QuickCoupler

Attachment

Piping for Breaker and Crusher (Optional)

AUX Function Lever for Extra Piping (Optional)

Precautions for Breaker Operation

Precautions for Crusher Operation

Control Lever (SAE-backhoe Pattern)

Fuel Feed Device (Optional) (ZX50U-5N, 60USB-5N)

Additional Counterweight

Cab Tilting Mechanism

INDEX

7. Operators Manual: Angle Blade (ENMADGNAOP13)

Format: PDF, 22 pages

Language: English

Included

Operation and Test Manual

1Troubleshooting Manual

1Repair Manual

1Engine Technical Manual

2Operators Manual

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Similar products